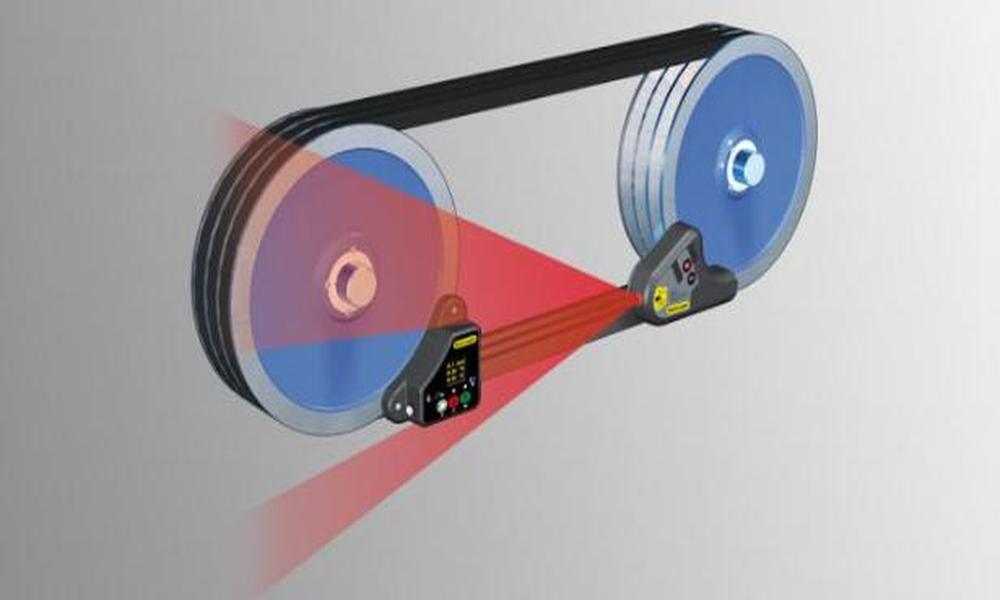

The use of laser technology in state-of-the-art belt pulley alignment has gained immense popularity in recent years. That is largely due to its accuracy and efficiency. Proper understanding and usage of these systems are crucial to achieving optimal results.

So, it’s worth exploring comprehensive guidance on the dos and don’ts of using laser technology for belt pulley alignment.

Do: Choose the Right Laser Alignment Tool

When selecting a laser alignment tool for your application, several factors must be taken into consideration. First and foremost, ensure that the tool is suitable for your specific requirements. Consider the type of belt and pulley system you are working with, as different tools cater to various belt sizes and machinery types.

Investing in a high-quality and reliable laser alignment system brings numerous benefits. These tools offer precise measurements, enabling accurate alignment of belt pulleys. Additionally, they enhance overall operational efficiency, reduce maintenance costs, and minimize downtime. Prioritize tools that provide clear and easy-to-interpret alignment readings.

Don’t: Neglect Regular Maintenance

Regular maintenance is vital to ensure the longevity and optimal performance of laser alignment tools. Neglecting maintenance can lead to inaccurate readings and compromised results. Follow these tips to keep your equipment in excellent condition:

- Clean the optics regularly to prevent dust and debris from affecting laser accuracy.

- Inspect cables and connectors for any signs of damage or wear.

- Calibrate the tool periodically according to the manufacturer’s recommendations.

- Store the tool in a suitable case or protective cover when not in use to prevent damage.

By incorporating regular maintenance practices, you can maximize the lifespan and effectiveness of your laser alignment tool.

Do: Follow Manufacturer Guidelines

To achieve accurate alignment and prevent potential damage, it is crucial to adhere to the manufacturer’s guidelines for tool setup and operation. These guidelines are designed to ensure optimal performance and user safety.

Carefully read the instruction manual provided by the manufacturer. Familiarize yourself with the recommended procedures for tool calibration, mounting, and measurement. Follow the prescribed steps diligently to achieve reliable and repeatable alignment results.

Don’t: Rely Solely on Superficial Inspection

While a cursory inspection can help identify obvious misalignments, it cannot measure the magnitude of the misalignment accurately. Laser alignment tools provide precise measurements, enabling you to make informed adjustments with confidence. Trust in the precision of your laser alignment tool and rely on its readings for accurate alignment.

Do: Train Your Team

Ensure that your employees understand the principles and operation of laser alignment tools. Train them on proper tool handling, calibration procedures, and interpretation of alignment readings. Encourage continuous learning and provide resources such as online courses, manuals, or training videos to support their development.

Don’t: Overlook Safety Precautions

While laser technology offers exceptional accuracy, it is crucial to prioritize safety when working with these tools. Laser beams can pose potential hazards to human eyes and skin. Here are some safety precautions to follow:

- Always wear appropriate personal protective equipment (PPE) when using laser alignment tools. This may include safety glasses or goggles that provide adequate laser protection.

- Avoid directing laser beams towards people or reflective surfaces to prevent accidental exposure.

- Make sure the working area is well-ventilated and free from flammable materials to reduce the risk of fire hazards.

- Follow any additional safety guidelines provided by the manufacturer for the specific laser alignment tool you are using.

By implementing proper safety measures, you can protect the well-being of your employees while utilizing laser technology for belt pulley alignment.

Conclusion

In conclusion, laser technology offers unparalleled accuracy and efficiency when it comes to belt pulley alignment.

By following the dos and avoiding the don’ts outlined above, you can optimize the performance and reliability of your machinery. Implementing these practices will contribute to more precise alignment, reduce downtime, and ultimately lead to better success in your operations.